Safety in Focus, Capturing Every Critical Moment

Advanced collision detection, real-time alerts, and video insights to increase safety and security in your facility. A set-and-forget, automated system to reduce accidents, reduce damages and regain control

Today's Reality

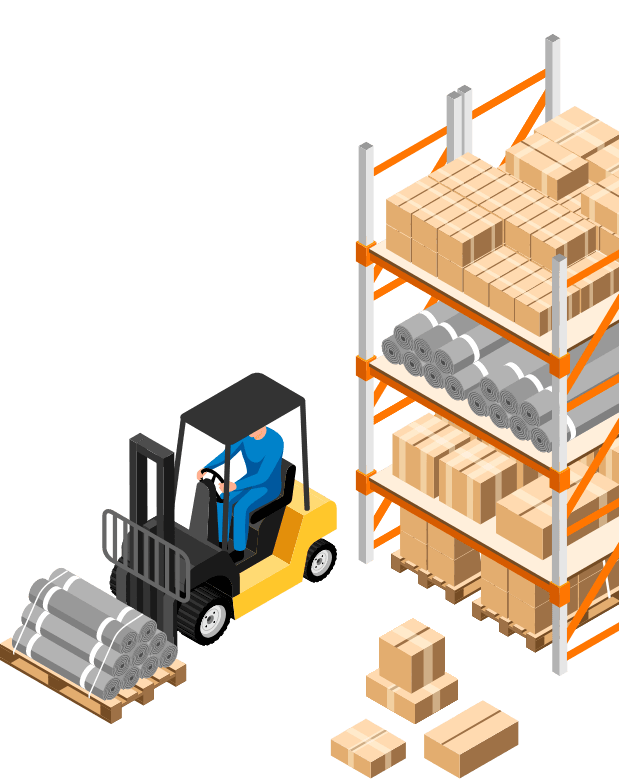

Warehouse environments are prone to frequent forklift collisions, often due to crowded spaces and fast-paced operations. When accidents or near-misses occur, there’s typically little context or detailed information about the incident, making it difficult to identify the cause and take preventive action. Employees may avoid taking responsibility, leaving management with unresolved and unknown safety concerns. These accidents result in high costs-not only from damaged equipment and merchandise but also from expensive repairs, operational downtime, and potential injury claims.

Statistics

-

85-100 yearly deaths due to forklift incidents

-

30,000 – 60,000 non-fatal forklift accidents per year, each averaging 3 week absences due to employee injuries

-

11% of all forklifts are involved in accidents each year

-

41,003$ average cost of workers compensation claim

-

73% of customers experience damaged materials and products due to warehouse incidents

-

Average fines of 13,494$ per safety violation

Why smart lifts

Our Plug & Play equipment is easy to install and works on any model of forklift or equipment. The sensor’s commercial magnets allow for an incredible freedom of placement and make discrete placement a thing of ease. Once installed, our guided 5-minute setup process will walk you through your system configuration. You’ll have your own personalized solution up and running in no time!

When an incident occurs, you’ll have access to all the information such as the incident’s Date & Time, Location, Collision Severity, Equipment’s Speed and Collision Angle. You’ll also have video footage of the incident with the equipment’s POV. Smart Lifts allows you to have eyes on every critical moment!

Our sophisticated algorithms along with our state-of-the-art sensors allow you to reconstruct collision events with complete precision. Visualize collision graphs showing impact severity per axis, collision angle, length of impact and overall force. This is all thanks to the 400 readings per incident that are recorded and analyzed by our sensors.

Though having collision data is great and often very helpful in determining the scale and location of potential damages, it’s limited in understanding an incident’s context and its root cause. That’s where our 4K camera with a 180° field of view comes into play! With every incident, you’ll have access to the moments leading up to and following the incident, providing you with all the context needed to truly understand what happened.

When an incident occurs, authorized personnel will receive encrypted, real-time notifications with all the collision information such as Date & Time, Location and Severity. Notifications also include video footage of the incident, allowing supervisors on-the-go to have access to the whole picture without needing to log into their portal.

All data is stored and secured in our cloud. Our high-end encryption and security mean your data will be safe, all while allowing you to have access to it anytime, anywhere and on any device, thanks to our easy-to-use web portal.

Smart Lfits is integrated with a suite of additional services such as Electronic pre-trip inspections, a detailed Maintenance and Repair management tool, a powerful Shipping and Receiving schedule and a detailed Warehouse Inventory and more. Whether you’re looking for a simple safety and security tool or a complete W.M.S, Smart Lifts and Eagle Eye allow you to manage all your operations seamlessly and efficiently.

Employers are held accountable for forklift accidents unless they can prove the incident occurred without their knowledge, due to employee negligence and despite safety measures. Smart Lifts offers the proof needed to demonstrate innocence, protecting employers and management from liability. In severe cases, such as those involving fatalities, penalties can include up to 10 years in prison and fines exceeding $350,000.

Forklift accidents cause major damage to warehouse infrastructure such as racking, walls, columns and guardrails which then require costly maintenance and repair. Equipment such as forklifts, racking and packaging are constantly being damaged due to collisions of all severity. Not to mention damaged inventory, leading to client penalties and harming your business reputation.

Smart Lifts meets many insurance audit criteria such as collision monitoring, risk assessment, camera surveillance and built-in anti-theft functionalities. We help companies improve their coverages and reduce exposure.

Up to 70% Reduction in Collisions

The effect

Our evaluations have shown that installing Smart Lifts can reduce your total number of collisions by up to 70%.

Less collisions means fewer near misses, a diminution of serious incidents and lower costs associated with damages.

SSO Integration with Azure AD and OKTA

100% Network independence – (Cellular or WiFi capability)

Encrypted Notifications

Multi-Site Management and Monitoring

Advanced Capabilities

Cloud Based Data

Configurable Users and Restrictions

Forklift Anti-Theft Functionalities

Flexible KPI Reporting

Bringing Safety Into Focus

Technical Specifications

- 4K Video and 180° Field of View

- 3-Axis Motion Sensor Recording

- 45 Day Backup Battery on Sensor

- 400 Motion Readings Per Second

- GNSS Location Tracking

- Sensor Intelligence

- LTE & Wifi Connectivity

FAQ

Can Smart Lifts be installed on all brands of forklifts? Even older forklifts?

Yes. Smart Lifts is compatible with all models of forklifts and vehicles. The sensor is installed with commercial magnets and provides accurate data regardless of the vehicle model.

Can there be multiple administrators? Can administrator views be restricted by location?

Yes. You can create multiple administrators and have the option to restrict their tracking by location. You can also restrict access to configurations and information by user.

Can I adjust the sensitivity of my alerts?

Yes. You can adjust the sensitivity by location to accommodate different operations and environments. Sensitivity can be adjusted over time to find the perfect configuration for your situation.

Can I install Smart Lifts on equipment other than forklifts?

Yes. Smart Lifts can be installed on any vehicle or equipment. The only requirement for installation is a power source. The sensor and camera format provides accurate data on all types of mobile equipment.

Can I install Smart Lifts without recording my operators?

Yes. The camera format and its flexibility in placement allow you to choose which elements are captured, including the front of the forklift, the forks, the operator's hands, or the operator as a whole.

Does the camera record continuously, or only during an incident?

Recording is continuous and is stored locally on the camera’s memory card. When an incident is detected, the video of the event is sent. Video recordings not associated with an incident remain available for transmission for a few days.

Can I manage multiple warehouses with my Smart Lifts?

Yes. Smart Lifts is multi-location and allows high-level and location-based tracking management.

Is the Smart Lift equipment under warranty?

Yes. All Smart Lifts equipment comes with a one-year warranty.

Will I receive incident alerts due to driving conditions and floor conditions?

No. Smart Lifts uses a sophisticated algorithm to analyze recorded data and distinguish real incidents from normal operations. Additionally, you can decrease or increase the sensitivity to receive your desired level of monitoring.

Is the installation of Smart Lifts complicated? Does it require a specialized technician?

The installation of Smart Lifts is very simple. The camera can be installed in multiple locations using the included mount and screws, the sensor attaches subtly with magnets, and everything connects to the battery.

Does Smart Lifts require a connection to our office/warehouse network?

No. Smart Lifts can use the local WiFi network but can operate 100% independently with the cellular network. The camera and sensor can transmit data via cellular, remaining parallel to your internal network.

Once I receive the equipment, is it complicated to configure?

Smart Lifts includes guided steps that allow you to configure your warehouses, vehicles, and users simply and quickly.

What is the delay between the incident and the notification?

Email and WhatsApp notifications are sent in real-time.

Are the data recorded by Smart Lifts secure?

Yes. Our data is secure and encrypted across two SOC 2 - Type 2 certified data centers. The system is also integrated with Azure controls to ensure high-level security.

Can Smart Lifts locate an incident inside a warehouse?

Yes. All sensors are equipped with satellite antennas to record precise positioning as well as the speed of the forklift. As long as the satellite network reaches the warehouse floor, we will indicate the exact location of the incident.

Speak with one of our Agents

Connect with ease—our team is here to answer your questions and provide straightforward information about our system, all in a single call. Rest assured, your contact details stay with us and your information is respected. Just clear, helpful support.

Clearer Vision, Safer Facilities